Lynx

Member

- Messages

- 2

- Location

- Scottish Highlands

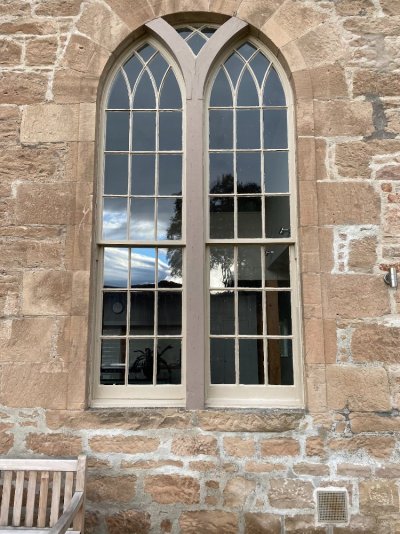

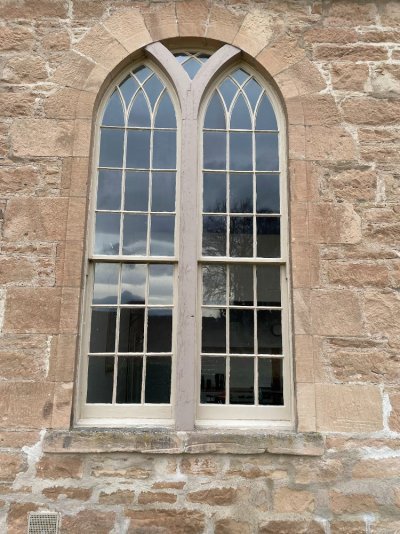

We paid just under £14k to have four large sash windows replaced in an 1800s church conversion in the Scottish Highlands. The goal was to reduce heat loss in our home. As far as I can tell, the joiner did a nice job in recreating the exact form of the originals, including their curves and details, despite incorporating double-glazed heritage glass panels for improved thermal insulation. The lower sashes slide up and down relative to fixed upper sashes.

Originally the joiner used staff beads without any brush seals and unfortunately the windows were rather difficult to open - requiring initial wedging from the outside to open - and there were air leaks in places. After we raised this issue, the joiner replaced the staff beads with smaller staff beads that incorporate brush seals. He used a nail gun to secure them in place.

But whilst the windows certainly slide more easily now, there are many air leaks in places where the brush seals fail to make contact and also between the staff beads and the frames to which they are attached. By air leaks, I mean feeling cold air pressing into your hand when it is cold outside. Misalignment in respect of the staff beads is also apparent because there are visible gaps between the lower sashes and parting beads when viewed from the outside, and if I press on the relevant corners from the inside, there is significant movement of the lower sashes. Also, when looking from above, one can see uneven gaps between the lower and upper sashes, particularly in one of the sash windows.

My gut is that the staff beading needs to be sized a little larger with a larger brush (or alternative seal?), better aligned against the lower sashes and more tightly pressed against them.

But actually I am also wondering whether to give up on the sash functionality altogether and simply fix the lower sashes in place and ensure air tightness all around. Given the size of these windows, slight leaks add up over large areas and tend to result in significant heat loss.

With these large windows spanning two floors, to what extent is achieving reasonable air tightness whilst ensuring ease of opening from the inside actually feasible?

I tried contacting various sash window experts, but they all seem booked up for about one year and unwilling to work on anything other than complete replacements.

I'd really value any thoughts or suggestions on the work undertaken and next steps going forward. We are on good terms with the original joiner and I can always ask him to come back, but I need to know whether to persist in trying to maintain the sash functionality or simply opt for fixing the lower sashes in place.

I enclose images below and here is a short video clip: https://photos.app.goo.gl/dqhfK44rgZm3acXn7

Originally the joiner used staff beads without any brush seals and unfortunately the windows were rather difficult to open - requiring initial wedging from the outside to open - and there were air leaks in places. After we raised this issue, the joiner replaced the staff beads with smaller staff beads that incorporate brush seals. He used a nail gun to secure them in place.

But whilst the windows certainly slide more easily now, there are many air leaks in places where the brush seals fail to make contact and also between the staff beads and the frames to which they are attached. By air leaks, I mean feeling cold air pressing into your hand when it is cold outside. Misalignment in respect of the staff beads is also apparent because there are visible gaps between the lower sashes and parting beads when viewed from the outside, and if I press on the relevant corners from the inside, there is significant movement of the lower sashes. Also, when looking from above, one can see uneven gaps between the lower and upper sashes, particularly in one of the sash windows.

My gut is that the staff beading needs to be sized a little larger with a larger brush (or alternative seal?), better aligned against the lower sashes and more tightly pressed against them.

But actually I am also wondering whether to give up on the sash functionality altogether and simply fix the lower sashes in place and ensure air tightness all around. Given the size of these windows, slight leaks add up over large areas and tend to result in significant heat loss.

With these large windows spanning two floors, to what extent is achieving reasonable air tightness whilst ensuring ease of opening from the inside actually feasible?

I tried contacting various sash window experts, but they all seem booked up for about one year and unwilling to work on anything other than complete replacements.

I'd really value any thoughts or suggestions on the work undertaken and next steps going forward. We are on good terms with the original joiner and I can always ask him to come back, but I need to know whether to persist in trying to maintain the sash functionality or simply opt for fixing the lower sashes in place.

I enclose images below and here is a short video clip: https://photos.app.goo.gl/dqhfK44rgZm3acXn7