Zebra

Member

- Messages

- 3,015

- Location

- St Albans, Hertfordshire

I have a handmade oak bannister in the bedroom, which is a bit wobbly. I used the normal modern method of securing bannisters (a hole up through the bottom and a nut which tightens through a hole in the side) and I guess what I was securing it to wasn't 100% flat, so it rocks a little from side to side.

Recently this thread about repairing doors suggested a method of drilling and securing either hardwood dowel or threaded rod, and I am wondering if I could use that method here.

http://www.periodproperty.co.uk/forum/viewtopic.php?f=1&t=16870

The bannister is directly above a main beam. I am thinking of drilling diagonally down through the bannister into the beam and inserting threaded rod which would bite into the timber of both. Presumably I wouldn't need to go more than a cm or two into the main beam, if the rod bites well. I don't think hardwood dowel would work, if it didn't adhere well to the beam then it would slide in and out of its hole and the bannister would still rock.

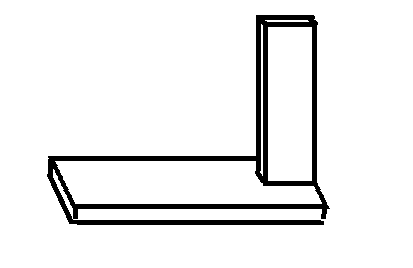

Here is the area from diametrically opposite viewpoints. The chalk marks on the top stair show where the beam is.

I realise using threaded rod makes it tricky to finish the job if you want to recess it below flush. If I ran it in and out several times and greased it, would it go smoothly enough to cut a slot in the end and do the last few turns with a screwdriver? Unlikely perhaps in very old oak.

Any other ideas? A steel angle buried beneath the top stair is an idea, although beneath the top stair there is 6mm ply, then the original boards, before you get to the beam. Also then you'd have to cover the bit that sticks up.

Thanks for any input!

Recently this thread about repairing doors suggested a method of drilling and securing either hardwood dowel or threaded rod, and I am wondering if I could use that method here.

http://www.periodproperty.co.uk/forum/viewtopic.php?f=1&t=16870

The bannister is directly above a main beam. I am thinking of drilling diagonally down through the bannister into the beam and inserting threaded rod which would bite into the timber of both. Presumably I wouldn't need to go more than a cm or two into the main beam, if the rod bites well. I don't think hardwood dowel would work, if it didn't adhere well to the beam then it would slide in and out of its hole and the bannister would still rock.

Here is the area from diametrically opposite viewpoints. The chalk marks on the top stair show where the beam is.

I realise using threaded rod makes it tricky to finish the job if you want to recess it below flush. If I ran it in and out several times and greased it, would it go smoothly enough to cut a slot in the end and do the last few turns with a screwdriver? Unlikely perhaps in very old oak.

Any other ideas? A steel angle buried beneath the top stair is an idea, although beneath the top stair there is 6mm ply, then the original boards, before you get to the beam. Also then you'd have to cover the bit that sticks up.

Thanks for any input!