fernicarry

Member

- Messages

- 872

- Location

- Argyllshire

I've just made myself a sash and the last thing I need to figure out is cutting the profile on the bottom to fit into the cill.

Here is the cill profile we use in this part of the world. The outside face of the sash sits in line with the small step to the right and the inner face of the sash overlaps the flat part by about a quarter inch.

Next shows the cill offcut offered up to the underside of an existing sash.

The bevel along the bottom is easy enough, track saw on outer face of sash with (I'm guessing) 5' undercut. What I'm stuck on is how to cut the rebate out of the inner face of the sash where it overhangs the top of the cill. I reckon the angle on the cill is 30' but its maybe half of that on the sash itself.

Best I can think of at the moment is a panel raising cutter. Either feed the whole sash across the table or use a guide rail to run the router across the sash. There are cutters with a 15' angle that would cut the straight edge into the face as well. Multiple passes required to get the depth I imagine.

However I'd prefer not to splurge on yet another cutter for this project (I've purchases at least 10 in the last few weeks....), and those large panel cutters are quite spendy, so can anyone think of another way?

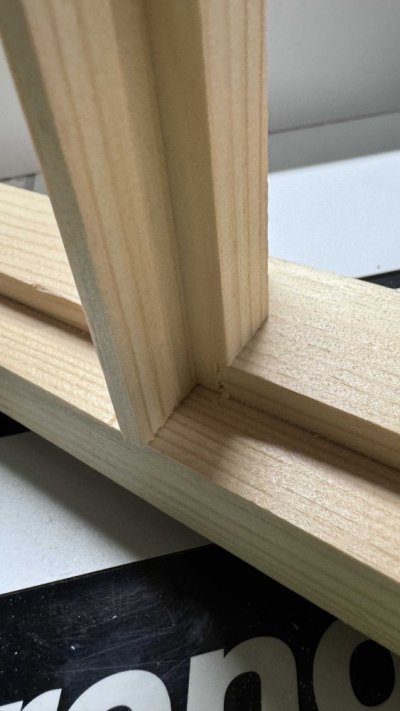

Here's the sash itself awaiting glue up. Its actually going to be a fixed light hence the extra rail in the middle to give the appearance of the meeting rail of a pair of sliding sashes. I'm quite chuffed with it considering its the first I've done with glazing beads!

Here is the cill profile we use in this part of the world. The outside face of the sash sits in line with the small step to the right and the inner face of the sash overlaps the flat part by about a quarter inch.

Next shows the cill offcut offered up to the underside of an existing sash.

The bevel along the bottom is easy enough, track saw on outer face of sash with (I'm guessing) 5' undercut. What I'm stuck on is how to cut the rebate out of the inner face of the sash where it overhangs the top of the cill. I reckon the angle on the cill is 30' but its maybe half of that on the sash itself.

Best I can think of at the moment is a panel raising cutter. Either feed the whole sash across the table or use a guide rail to run the router across the sash. There are cutters with a 15' angle that would cut the straight edge into the face as well. Multiple passes required to get the depth I imagine.

However I'd prefer not to splurge on yet another cutter for this project (I've purchases at least 10 in the last few weeks....), and those large panel cutters are quite spendy, so can anyone think of another way?

Here's the sash itself awaiting glue up. Its actually going to be a fixed light hence the extra rail in the middle to give the appearance of the meeting rail of a pair of sliding sashes. I'm quite chuffed with it considering its the first I've done with glazing beads!